Digital transformation of a manufacturing process in the pharmaceutical industry: A guide

Background

In the dynamic world of the pharmaceutical industry, the digital transformation a decisive factor in securing competitiveness and developing innovative solutions. In the context of Pharma 4.0 in particular, it becomes clear how advanced digital solutions can not only increase efficiency, but also significantly improve product quality. In this blog article, we highlight a specific use case of digital transformation in the chemical industry that serves as a model for Consulting Pharma.

Current status at our customer

A complex manufacturing process chain in the chemical industry produces several tons of a product in different variants every day. A key cost factor is the time required for product changeovers. Although attempts are made to produce large batch sizes, customer orders tend to demand ever smaller and shorter-term quantities.

The changeover process usually takes 2 to 3 hours and requires precise coordination of the various production steps. During this time, the product produced is considered waste and must be reprocessed. Some of these processes are subject to a statistical process control (SPC), while others rely on classic in-process control (IPC), using only manual sampling and laboratory analyses.

Negative effects

The overall process is difficult to control, as various sub-processes have to be synchronized. The release of critical preliminary stages is dependent on laboratory analyses, which leads to considerable delays in the event of disruptions or rapid product changes. These inefficiencies not only affect the production flow, but also the overall costs.

Although raw materials meet specifications, they exhibit different behaviors in production operations. This means that less experienced operators, relying on their experience, are not always able to keep products within specification. The cost of production errors is significant, as these problems often only become apparent after batch production has been completed.

Our solution for the customer

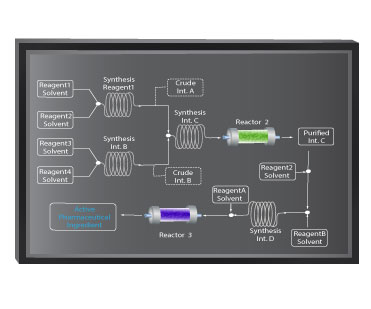

The central challenge is to optimize the changeover from one product variant to the next of the same basic product. To achieve this, an important focus was placed on digitalization. Digital transformation was not only seen as a step towards automation, but also forms the basis for future optimizations in free consulting for companies within the pharmaceutical industry.

Identification of the most important parameters

For the successful implementation of the project, all measurements that are currently not linked online, including raw material analyses in the laboratory and final product checks before shipping, must be identified. This identification is essential for a successful digital transformation in the pharmaceutical industry.

Linking the data

The next step is to link the manual measurement data with the information already generated by existing SPC systems. The software available on the market is often not sufficient. This is why we develop individual software solutions in our Consulting Pharma division that are tailored precisely to the needs of our customers. With this customized software, hidden correlations can be uncovered, such as the influence of excipients on the specification parameters.

Advantages: Data integration for well-founded decisions

The integration of all generated data into a centralized system offers numerous advantages. In the previous system, incoming inspections were only considered as "pass/fail", which meant that raw material variations were not integrated into the production process. However, the new system makes it clear whether and how raw materials vary in their incoming quality and what influence this has on the end product. This valuable data now enables active control of product quality and promotes the digital transformation of the pharmaceutical industry.

A key advantage of the new system is the quantification of empirical values. The quality of the end product no longer depends solely on the individual plant operator, but becomes more consistent and predictable thanks to the improved possibilities for data analysis.

Increased efficiency through faster product changeover

With the new system, product changeovers can be carried out considerably faster - from several hours to just around one hour. This not only leads to a general increase in efficiency, but also to a reduction in manufacturing costs, which represents a competitive advantage in the pharmaceutical industry.

The new system also enables quality trends to be identified more quickly. In this way, an excipient that has a significant influence on product quality can be detected quickly. Even if all qualities offered on the market meet the legal requirements, the raw material properties - such as the morphology of the particles - play a decisive role in product quality. Thus, by selecting the right supplier, a higher quality product can be produced at the same price.

Faster new development

The development of new product variations has been significantly simplified and accelerated by advances in digitalization. With the new model, the necessary system parameters can be predicted much more precisely in future. Even small test series in the laboratory or pilot plant are now sufficient to precisely determine the machine settings. As a result of these optimizations, development times have been reduced to just 20 % of the original time. This increases the company's flexibility and ability to respond quickly to customer requests.

Conclusion

In summary, it can be said that the digital transformation of a manufacturing process in the pharmaceutical industry is not just a technical advance; it is revolutionizing processes in a profound way. The use of state-of-the-art technologies not only increases efficiency, but also achieves higher product quality - a benefit for all stakeholders in the pharmaceutical industry. Value chain.

Another important aspect of digitalization is improving collaboration both internally within the company and externally with partners. Digital platforms enable the smooth exchange of information between different departments such as research and development, production and quality assurance. This networking accelerates decision-making processes, as all relevant data is available in real time.

In a world that is constantly changing, digital transformation stands out as an indispensable element in the pharmaceutical industry and in consulting pharma. By taking proactive measures and utilizing the latest technologies, companies can not only overcome challenges, but also seize new opportunities and position themselves for the future.