- Pharma Consulting

- Products

- 1 Intelligent scale-up

Process development & digitalization - 2 Process

Optimization - 3 Precise freeze-drying

- 4 Polarized light -

Optical inspection - 5 Process analytical technology

PAT and AI - 6 Process

Validations - 7 Method transfer

Technology transfer - 8 Quality

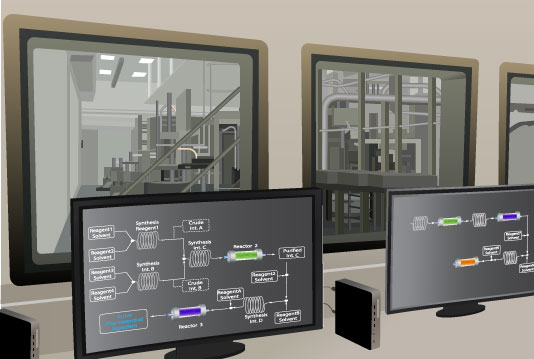

Management and GMP - 9 Virtual factory

Simulation - 10 Project management

- 1 Intelligent scale-up

- Case studies

- About us

- Pharma Consulting

- Products

- 1 Intelligent scale-up

Process development & digitalization - 2 Process

Optimization - 3 Precise freeze-drying

- 4 Polarized light -

Optical inspection - 5 Process analytical technology

PAT and AI - 6 Process

Validations - 7 Method transfer

Technology transfer - 8 Quality

Management and GMP - 9 Virtual factory

Simulation - 10 Project management

- 1 Intelligent scale-up

- Case studies

- About us

- Pharma Consulting

- Products

- 1 Intelligent scale-up

Process development & digitalization - 2 Process

Optimization - 3 Precise freeze-drying

- 4 Polarized light -

Optical inspection - 5 Process analytical technology

PAT and AI - 6 Process

Validations - 7 Method transfer

Technology transfer - 8 Quality

Management and GMP - 9 Virtual factory

Simulation - 10 Project management

- 1 Intelligent scale-up

- Case studies

- About us