Technology transfer

Process development

Outsourcing CMO Efficiency increase

Creating more value - through rapid technology transfers

and efficiency increase

Strengthening pharmaceutical excellence

12+

12 + years

59+

Projects Europe, USA and Asia

75%+

Corporations

10% Start Up Biotech Customers

500

Millions - our biggest project

WHAT WE DO We carry out technology transfers in the pharmaceutical industry. We develop and optimise technical and administrative processes.

You thus achieve higher efficiency and high added value.

And all this in compliance with GMP rules.

Increase Efficiency

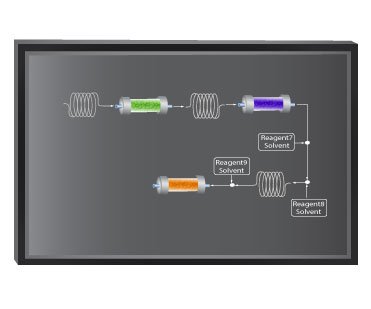

Ensure efficient scaling and continuous production:

Integration of quality-by-design methods and process analytical technologies.

Maximising Effectiveness

Rapid market launch

Facilitating technology transfer

in the pharmaceutical industry: accelerating market entry while complying with regulatory requirements, with innovation.

Optimised solutions

Products Our products for a dynamic world

Cooperation Strong partnerships lead to good results

Time saving

Rapid market entry through our experience: Accelerated technology and process transfer to improve cost efficiency and maximisation

the value added

Right strategy

Seamless technology transfer and outsourcing: effectiveness and efficiency lead to continuous improvement for competitive advantage

Simple processes

Simplify processes, shorten lead times and increase added value.